Fridge doors - how much energy do they really save? (Part 1)

It is often claimed in supermarket refrigeration that fridge doors deliver energy savings of 60% or more compared to open-fronted cabinets. These figures are almost always based on laboratory tests, usually comparing a doored and open cabinet under ISO climate class 3 (CC3) conditions.

But supermarket trials paint a different picture when it comes to supermarket energy technologies. Most report much lower savings from fridge doors: typically between 20% and 30%, and sometimes less.

So who is right? And if the real savings are closer to 20–30%, where is the rest going?

This performance gap raises serious questions about how these savings are calculated and whether they hold up under real trading conditions.

Lab testing methods tend to inflate the energy use of open cabinets, which skews the results. At the same time, some elements of testing can artificially boost the apparent performance of doors. The result is that doors may appear to offer 60%+ savings, but these are rarely achievable in store environments.

More importantly, lab tests do not account for the way fridge doors behave in use. Door-opening frequency, open duration, restocking events, online order picking, and degraded or missing seals all impact performance, but none are reflected in standard test assumptions.

In this article, we will look at why standard testing does not reflect real-world performance, what happens when more realistic conditions are applied, and why the comparison point for fridge doors needs to change, especially for retailers already using aerodynamic shelf-edge technology.

We will focus here on hinged doors, which are the most common in large-format supermarkets. (A future article will look at how sliding doors compare.)

Before diving into testing, we will start with a common misconception often aimed at supermarkets…

“Why don’t supermarkets have doors on their fridges? I have a door on mine at home”

It is a common argument, and on the surface, it sounds logical. But the comparison falls apart quickly.

Firstly, the two types of refrigeration are very different. Domestic fridges are statically cooled, whereas supermarket fridges circulate air with fans, which form a cold air curtain.

Most supermarket fridges have six doors per fridge, and they are only saving energy when all of them are closed. When any of the doors are open, the entire fridge uses more energy than a fully open cabinet. This is due to the bellows effect: the act of opening fridge doors drags cold air out of the fridge, allowing warm air to rush in, which increases cooling demand. Then, whilst the doors are open, convection causes air to move more dynamically through the opening, creating more cold air spill than in a fully open cabinet.

Domestic fridges have one door with a frame and gasket, so they are fully airtight when closed. Supermarket fridge doors cannot be made airtight when closed, so they aren't as effective, even when they are all closed.

What is more, domestic and commercial fridges also operate in entirely different environments and, crucially, thousands of people do not enter domestic kitchens and open the fridge door every few seconds. In supermarkets, that is precisely what happens.

In fact, tests by Aerofoil Energy (Sarno, 2019) found that:

With all six doors closed, the fridge used less energy than an open-fronted cabinet.

But if just one of the six doors was opened, energy use exceeded that of the open cabinet, even though the other five remained shut.

The real-world takeaway? Fridge door efficiency depends on how often the doors are opened and how long they stay open. In busy stores, where shoppers are constantly accessing chilled products, the energy advantage of doors quickly erodes.

So while the comparison to a home fridge might feel intuitive, it ignores the scale, environment, and behaviour that define supermarket refrigeration.

The testing assumptions behind door claims

Test chambers are configured to challenge cabinet performance under extreme conditions, rather than to replicate supermarket environments. This is essential to ensure food is stored safely, even in adverse scenarios. To do this, ISO Climate Class 3 test conditions stipulate:

25°C ambient temperature

60% relative humidity

Cross-draughts of 0.2 m/s

These conditions significantly affect the energy use of open cabinets. In lab tests, the cross-draught pushes warm, humid air into open fridges, disrupting the cold air curtain and increasing infiltration, which inflates energy consumption.

Doored cabinets, by contrast, are largely shielded from these effects.

This is where the discrepancy begins. In laboratory conditions, open cabinets appear far less efficient than they would be in real stores, while the performance of doored cabinets is overstated.

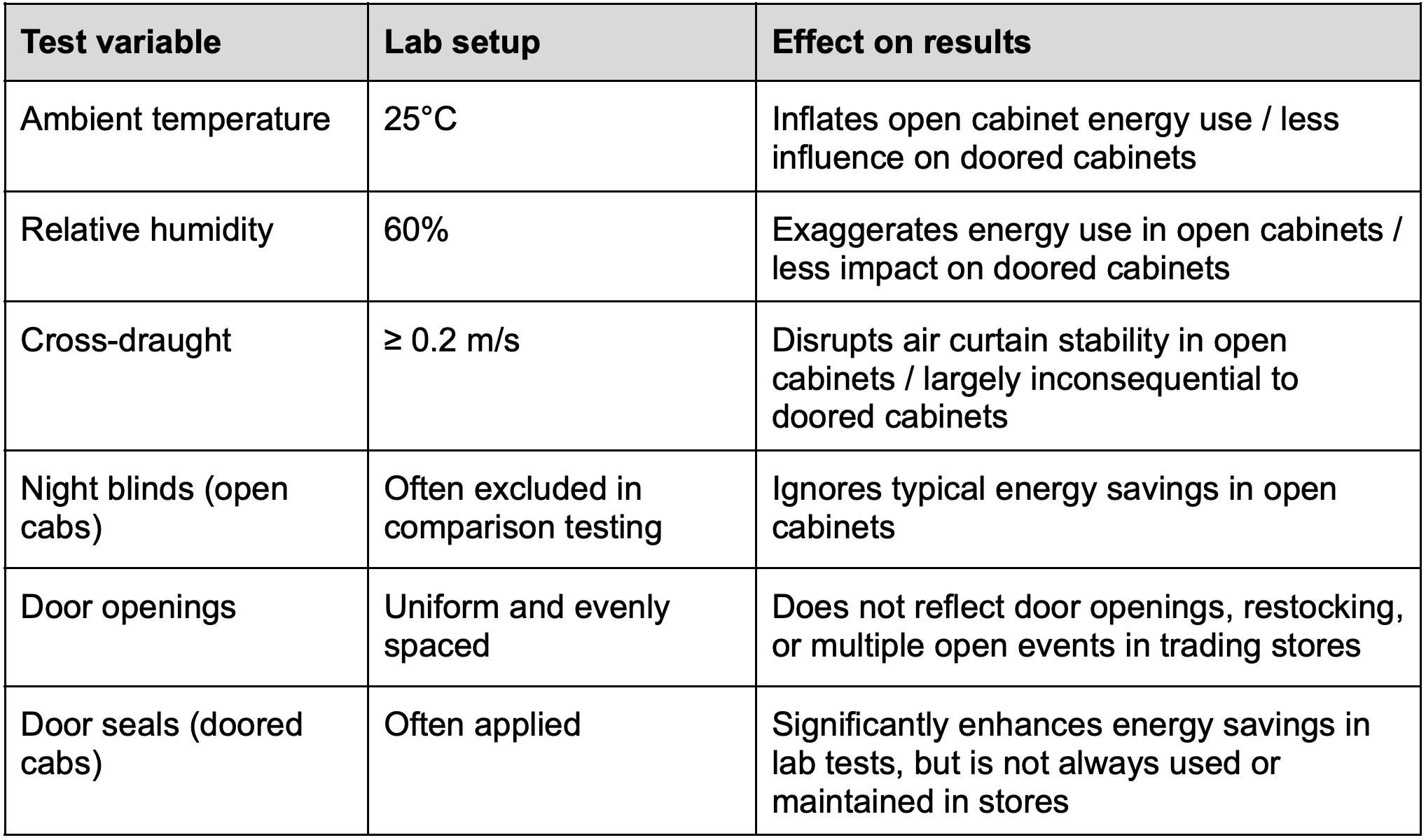

Here is how the most common variables affect results in a standard lab test:

While many engineers recognise that test chambers do not reflect live operation, what is often overlooked is how unevenly these artificial conditions affect different cabinet formats.

The common assumption is that testing both cabinets in the same environment yields a fair comparison. But that only holds true if the test conditions are neutral, and they are not.

The primary objective of the ISO test is food safety, not energy efficiency. It is designed to confirm whether cabinets can maintain safe storage temperatures under harsh conditions, not to produce accurate energy use data. Any efficiency claims derived from this setup are, by design, unrepresentative.

Field trials tell a different story

Multiple studies based on in-store trials or store-representative conditions support this:

Hill, Watkins and Edwards: 20–35% energy saving with doors

Axell and Fahen: 26% energy saving from door retrofits

ASDA: Aerofoils alone reduced cooling capacity by 34% across 187 stores

These are not isolated cases. They reflect what is happening in real stores, across large estates, under normal trading conditions, rather than artificial test conditions.

Understanding the root of the claimed savings is the first step. The next is examining what standard testing overlooks and how those gaps further distort the comparison between doored and open formats.

What standard supermarket fridge testing leaves out

Even when test comparisons seem fair - same temperature, same cabinet types - the conditions and behaviours that matter most in stores are either oversimplified or excluded entirely.

Here are the three biggest ways current testing methods overstate the energy performance of doors:

1. Inflated baseline conditions

As previously outlined, lab tests subject open cabinets to warm, humid air blown across the cabinet face. This destabilises the cold air curtain and significantly increases energy use. Doored cabinets, on the other hand, are shielded from this effect. The doors simply deflect the airflow.

The result? Open cabinets appear far less efficient than they are in real-world use, while doored cabinets are unaffected. The comparison becomes skewed from the outset.

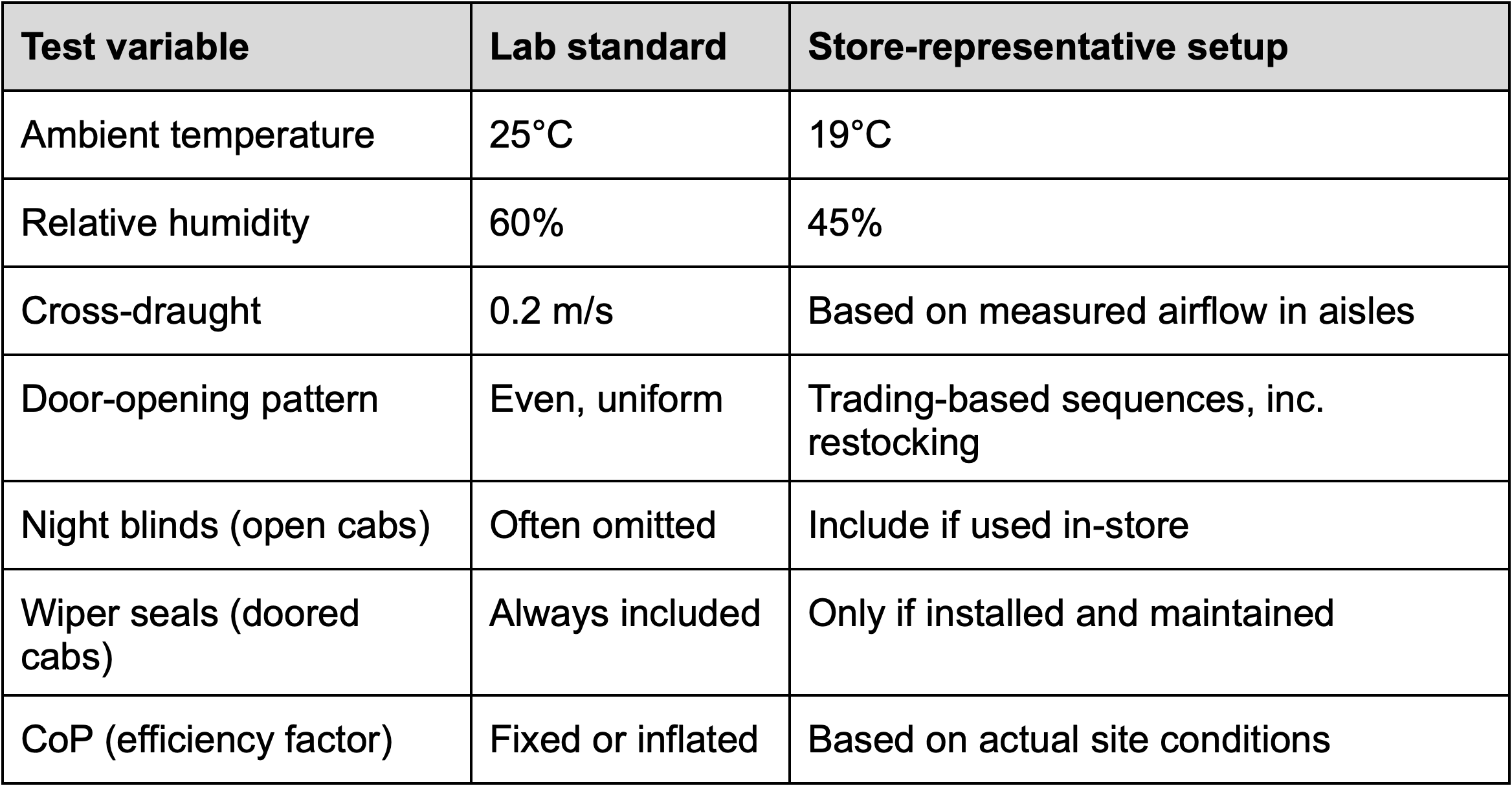

When more realistic parameters are applied — lower ambient temperature, reduced humidity, and store-representative airflow — the energy gap shrinks. Savings do not vanish entirely, but they fall to around 25–30%, not the often-quoted 60%.

2. Unrealistic door-opening sequences

Another issue is the way tests simulate shopper behaviour. Standard tests simulate door use with a uniform sequence: one door at a time, evenly spaced, opened for the same duration. But this bears little resemblance to real store behaviour. In practice, doors are:

Opened simultaneously by multiple shoppers

Held open during restocking

Repeatedly used for online picking during peak periods

Here are two graphs comparing the door opening profile specified under ISO conditions in a lab environment, versus actual observed openings in a trading store:

In the Sarno (2019) study, changing only the opening pattern — not the number of openings — reduced observed energy savings by 10%.

3. Test methods that skew the result

Some practices, while technically compliant, further distort results in favour of doored cabinets:

Night blinds: Many stores use night blinds during non-trading hours (a standard energy-saving measure on open cabinets). Whilst ISO tests of open cabinets stipulate night-blinds be used, in comparative lab tests, night-blinds are often excluded, artificially boosting the perceived advantage of doors. When night blinds are correctly accounted for, the energy gap shrinks significantly, especially in stores where blinds are deployed 12 hours a day.

Wiper seals: To pass ISO tests, fridge doors are often fitted with transparent rubber seals that create an airtight closure. These seals help reduce leakage in the test environment, but are rarely installed or properly maintained in stores. They are prone to failure, hard to clean, and susceptible to bacterial growth, which leads to removal. Without them, airflow effects pull large volumes of warm air into the fridge through door gaps, reducing the real-world energy benefit.

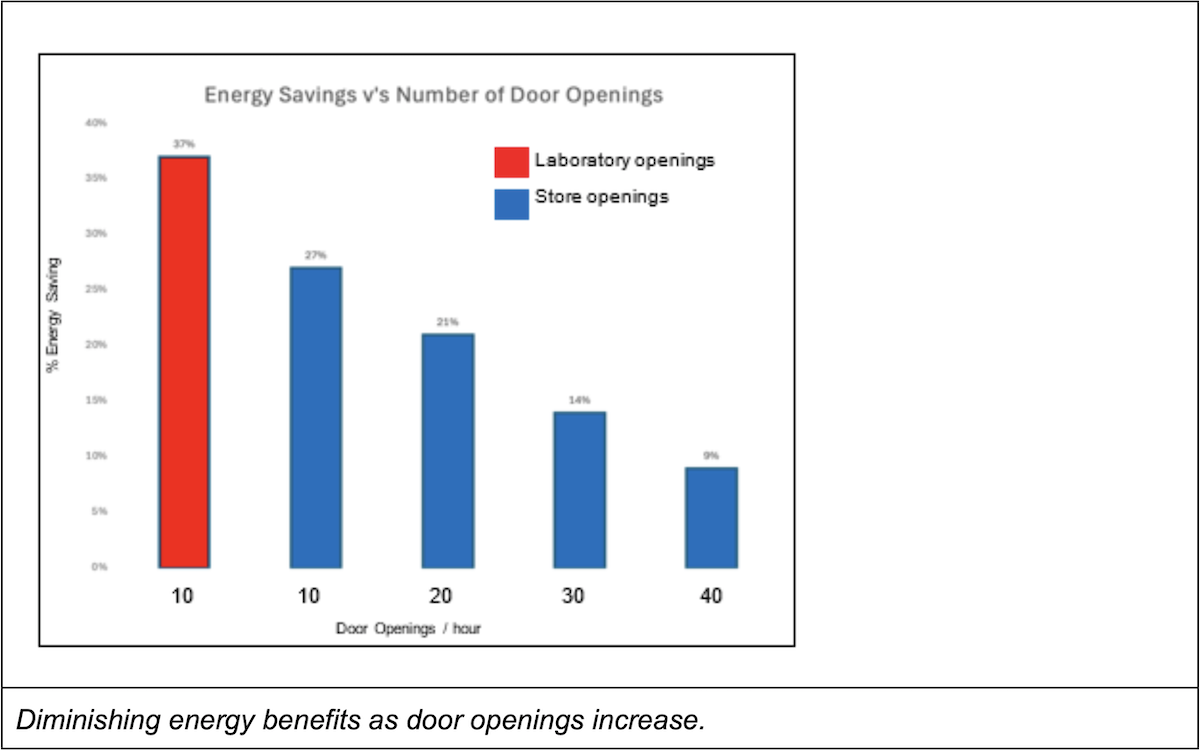

Door opening frequency: Standard testing assumes fridge doors open 10 times per hour, as in the Sarno study that found a 27% energy saving. But store data suggests real usage can be far higher and more chaotic: studies cite 60 to 250 openings per hour (Orlandi et al., 2013; EPEE/Eurovent, 2011).

Follow-up testing in the Sarno study showed that for every additional 10 openings per hour, the energy savings from the doors reduced by 10%. At 40 door openings/hr, the energy benefit from the doors dropped to just 9%, significantly lower energy savings than are achieved by installing aerofoils to open cabinets.

These losses demonstrate that long-duration openings and multiple simultaneous door events drive energy spikes, but these are not reflected in ISO testing.

In summary, there are many reasons why lab-tested energy savings rarely match real-world results. Together, these factors explain the consistent discrepancy and why retailers typically report 20–30% savings, not 60%+.

Rethinking the baseline

Even if testing were altered to simulate store conditions (more accurate door-opening sequences, more realistic airflow, and proper use of night blinds and seals), the comparison would still be incomplete.

That is because most UK retailers should no longer compare fridge doors to bare open cabinets. They should compare them to open cabinets already fitted with aerodynamic shelf-edge technology.

The real benchmark is not a bare cabinet

Over the past decade, aerodynamic upgrades have become part of the standard spec in many estates. So the comparison is not against a default open cabinet. It is against one that has already been optimised.

Aerofoil shelf-edge technology is now deployed at scale. ASDA’s 2018 trials across 187 stores showed a 34% reduction in cooling demand under controlled testing. In live store environments, results have remained consistent, with typical energy savings of 15–20%, measured under real trading conditions, not artificial test settings.

More recently, Aerofoil Energy launched a passive airflow kit for open-fronted fridges. It delivers energy savings comparable to traditional fridge doors, without the full-life cost, complexity, or disruption, while maintaining the open design retailers and shoppers prefer.

These and other aerodynamic innovations offer a viable alternative to full door retrofits and signal a new direction for supermarkets pursuing efficiency without compromise.

Keen to learn more? Watch this video:

When that level of optimisation is already in place, the additional benefit from doors becomes marginal. Store-representative testing puts the remaining energy gap at under 5%, and in some cases, doors offer no further energy reduction at all.

What accurate benchmarking should include

If the goal is to compare supermarket energy technologies based on real performance, then the testing setup needs to reflect how cabinets operate in stores. That means going beyond ISO certification and using parameters that mirror everyday trading environments:

Apply that framework, and the energy gap looks very different. In many cases, doors are only slightly more efficient than open cabinets that already use aerodynamic shelf-edge technology.

Factor in the added cost of maintenance, operational costs and evidence that doors can reduce food sales, and that small margin becomes harder to justify. Especially when Aerofoil systems are already delivering the majority of the savings without adding complexity at store level.

Here are just a couple of examples (click for the full stories):

Marks and Spencer chooses Aerofoils for eco-friendly efficiency:

Sainsbury’s claims Aerofoils have cut energy use across UK stores by 15%:

Balancing gains with reality

Fridge doors can deliver some energy savings in real-world use, but they are typically modest, and far below the 60%+ figures often quoted. In practice, retailers report closer to 20–30%. And in estates already using aerodynamic shelf-edge technology and/or night blinds, any additional benefit is often negligible (less than 10%). Once wider costs and sales impacts are factored in, doors can even result in a negative return on investment.

Whether doors represent a viable investment depends on a wide range of variables:

Store format and aisle layout

Airflow and cabinet specification, e.g, night-blinds

Shopper traffic and door-opening frequency

Use of technologies like Aerofoils

In heavily shopped cabinets, extended open-door periods and the bellows effect can push energy use higher than that of a well-optimised open cabinet.

That is why refrigeration strategies need a more nuanced approach. Aerodynamic innovations are now matching, and in some cases exceeding, the efficiency of traditional fridge doors, without the complexity, cost, or shopper disruption. As a result, open-fronted cabinets are fast becoming the new operational and environmental benchmark.

The greatest opportunity lies in targeted deployment. Doors may still make sense in low-traffic or specialist zones, especially where night blinds cannot be used. But in high-traffic areas, optimised open cabinets often perform better. A store-by-store analysis of shopper traffic and cabinet performance can help retailers identify where (and whether) doors make sense.

And if doors only deliver a marginal gain, or no gain at all, over an optimised open cabinet, the question becomes: is the cost really worth the trade-offs?

At Aerofoil Energy, we help retailers benchmark refrigeration performance using live store data, from shopper patterns and airflow to restocking and maintenance impact. We provide side-by-side comparisons and performance simulations to support strategic decision-making across your estate.

Coming next: In part two, we will analyse the wider commercial impact of fridge doors and how this influences ROI. To be the first to read it, follow us on LinkedIn or visit our blog.

If you are reviewing refrigeration strategy, we are here to help. Get in touch.

P.S. Heading to EuroShop 2026? Come and see real-world airflow performance in action.