Invisidoor™ for open refrigerated display cases: Cutting energy without doors

Supermarkets choose open refrigerated display cases because they remove barriers to buying. But this “shopper-first” format can come with an engineering cost.

Over 80% of the energy consumed by open chiller cabinets goes into maintaining the cold-air curtain. When that curtain weakens, cold air spills into the aisle, creating uncomfortable “cold aisle” conditions that stop shoppers from lingering. Warm air is absorbed into the cabinet, which means the refrigeration system has to work harder, and consume more energy, to maintain temperature.

We often hear from retailers who feel forced to choose between the energy efficiency of glass doors and the trading benefits of open fronts.

The good news? You no longer have to choose.

This article explores how Invisidoor™ stabilises the air curtain to deliver the efficiency you need without adding a physical barrier, and how its aerodynamic design solves the core performance issues that have limited open-fronted refrigeration for decades.

Why standard air curtains struggle to cope

An open refrigerated display case relies on a continuous “curtain” of cold air descending from the canopy to the return grille at the base. In theory, this curtain creates an invisible seal that keeps the cold air inside the cabinet and the warm store air out.

In reality, this curtain is incredibly fragile. As the air falls, it loses velocity and structure. The natural turbulence of a busy store, such as shoppers passing, HVAC draughts, and external doors opening, disrupts its path.

When the air curtain breaks, two things happen immediately:

Cold air spills out

Cold air is denser than warm air. Without a stable curtain to contain it, it “falls” out of the cabinet and pools on the floor, creating cold-aisle discomfort, which discourages shoppers from dwelling.

Warm air infiltrates

Ambient air is also drawn into the cabinet. To compensate, the refrigeration system works significantly harder to maintain set point temperatures.

Essentially, this creates a cycle of inefficiency:

Higher energy consumption: The refrigeration system has to work harder, and use more energy, to remove warm air ingress.

Temperature drift: Mixing flows creates hotspots, risking food quality and increasing waste.

Engineering strain: Compressors work harder and longer, shortening asset lifespan.

The standard open case was engineered for shopper access, not airflow control. Left unassisted, it operates like a cabinet with a permanent escape route for cold air.

How Invisidoor™ transforms the open fridge

Retailers need a solution that fixes airflow dynamics without changing the fundamental nature of the open cabinet.

Invisidoor™ is a passive aerodynamic system for open fridges that delivers the same (and in some cases more) energy savings as fridge doors, but without the drawbacks.

There are no moving parts, no physical barriers to shoppers or store staff, and nothing to maintain or clean.

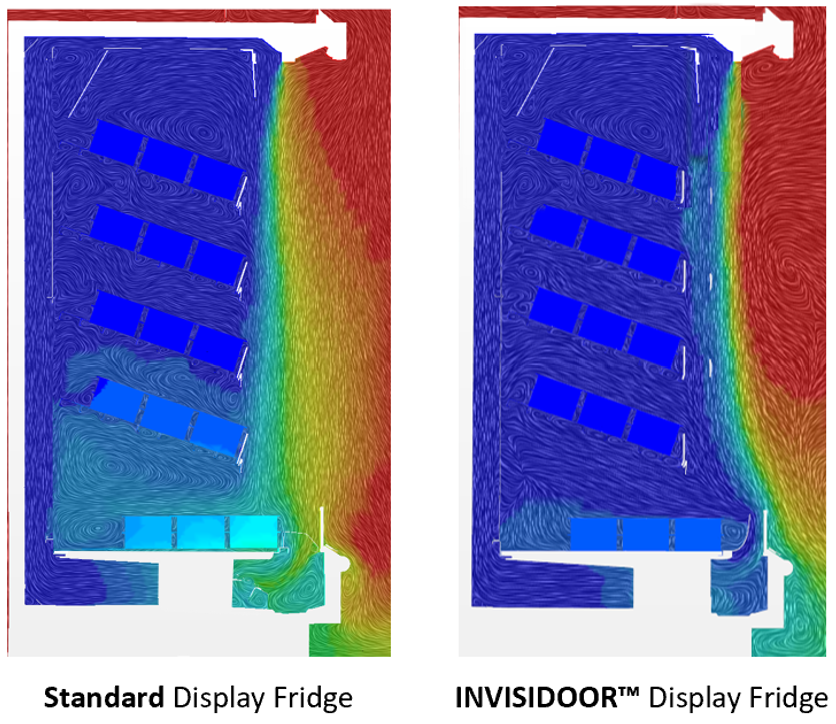

Rather than sealing the cabinet with glass, Invisidoor uses precision-engineered components, developed using advanced CFD (Computational Fluid Dynamics), to reshape and stabilise the cold-air curtain.

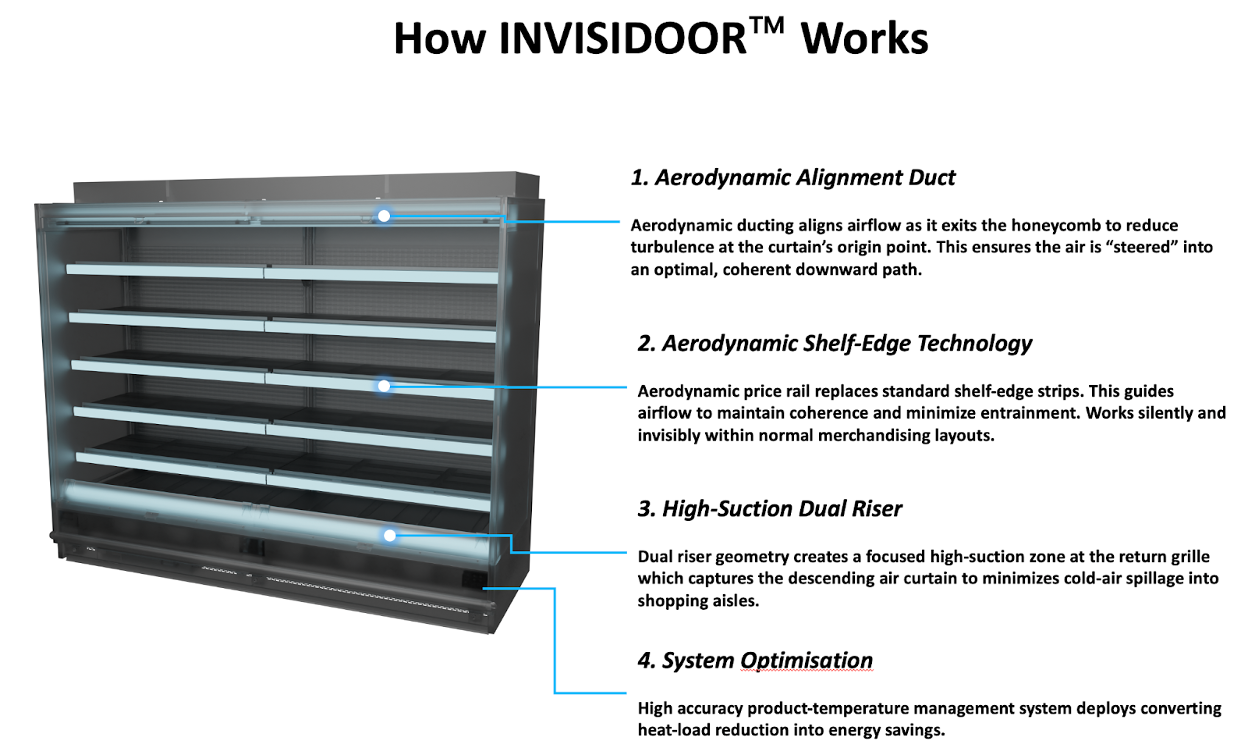

The system comprises several integrated aerodynamic elements and system optimisation technology to mitigate heat ingress and deliver large energy savings:

1. Aerodynamic alignment duct: stabilising the curtain at its origin

2. Aerodynamic shelf-edge technology: guiding the air through the cabinet

3. High-suction dual riser: capturing the curtain at its weakest point

4. System optimisation: turns heat-load reduction into energy savings

Together, these passive components create a continuous, stabilised airflow path. The cold air remains within the merchandising envelope, not because it is blocked by a door, but because the airflow has been engineered to stay where it belongs.

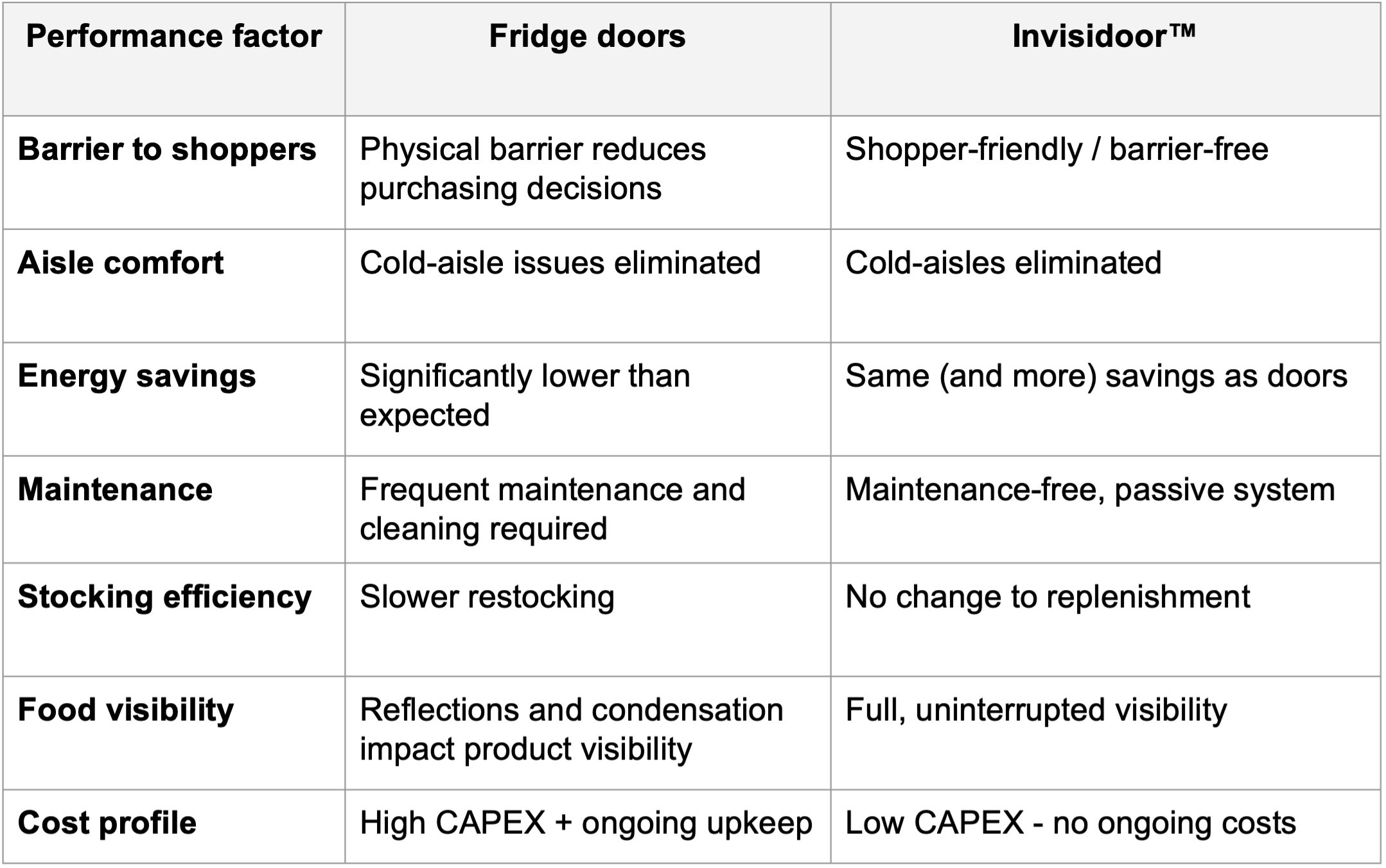

Invisidoor™ vs traditional approaches: understanding the options

Of course, retailers have more than one path to improving refrigeration performance. Doors remain an appropriate solution in some formats.

Invisidoor simply offers a different mechanism for achieving the same efficiency objective, with distinct commercial and operational advantages.

Here is a quick comparison:

The top three benefits of Invisidoor™

To understand the full impact of Invisidoor™, it helps to look beyond airflow alone. In practice, the benefits show up differently for every part of a retail organisation. As a result, the technology supports multiple priorities at once, from energy performance to trading efficiency to shopper experience:

#1. Energy efficiency:

Invisidoor provides measurable improvements in refrigeration performance that directly support operational cost targets:

25%–38% energy savings (based on airflow improvements)

Reduced load on the central plant

Reliable return on investment (payback typically <18 months)

Demonstrated Ecolabel compliance (several open-case models already achieving C-Rating after retrofit)

#2. Improved merchandising:

Secondly, Invisidoor helps maintain the trading characteristics that matter most on the shop floor. Because the system is completely passive, it integrates seamlessly with daily operations, ensuring stores remain easy to run and appealing to shop in:

No change or added costs to stocking speed

Full visibility and open access maintained

No doors to clean or maintain

Stable product temperatures → better food quality, less waste

#3. Benefits for the shopper:

Finally, Invisidoor supports the part of the store experience that customers feel every day. By stabilising the air curtain and reducing cold spill, it creates a noticeably more comfortable environment, which encourages shoppers to linger longer in chilled aisles:

Warmer aisles with no cold-air spill

Barrier-free browsing

Fresher, more consistent product temperatures

A more pleasant, higher-dwell shopping experience

Combined, these benefits show how Invisidoor strengthens performance across the store, from energy use to trading and shopper experience. It improves efficiency, simplifies operations, and enhances the customer journey, all while preserving the open-fronted format retailers prefer.

See Invisidoor™ in action

Invisidoor is already enabling open-fronted cabinets to meet efficiency standards previously associated with doors, while preserving the shopper-first format retailers prefer.

To review performance data, installation options, or arrange a technical discussion with our team:

👉 Visit the Invisidoor webpage

👉 Or contact information@aerofoil-energy.com

If you still have unanswered questions, you might like our most frequently asked questions, below.

FAQs

Does Invisidoor™ replace fridge doors?

In many large-scale installations, yes. Invisidoor is a proven, high-performance replacement for fridge doors, delivering door-level efficiency without a physical barrier. Doors remain suitable for some formats, but Invisidoor offers a definitive alternative for barrier-free shopping.

How does Invisidoor compare on energy savings?

Invisidoor delivers the same (and higher) energy savings as fridge doors for open cases, thanks to a fully stabilised air curtain.

Is Invisidoor suitable for all cabinet types?

Invisidoor is compatible with most open multideck configurations. Aerofoil Energy provides testing guidance and OEM integration support.

Does it require maintenance?

No. Invisidoor is a fully passive system with no moving parts, no electrical components, and nothing to service.

Can Invisidoor help with ecolabelling?

Yes. Invisidoor has recently enabled multiple open-case models to raise their listings from E-F, to achieve C-Rating under the European ecolabelling scheme. Note: The vast majority (87%) of doored cabinets listed on EPREL are D-C rated, demonstrating that passive airflow engineering meets regulatory benchmarks without the need for doors.

As of the time of publication, more cabinets are under test with Invisidoor technology applied, and in 2026 it is expected that several models will achieve B-ratings and be listed on EPREL, setting them well above the Ecolabel ratings of the vast majority of doored cabinets.