Refrigeration Technology: Why an investment case should be based on probabilistic models

When retailers evaluate supermarket refrigeration investments, the analysis often relies on a straightforward and simplistic model. Energy prices are fixed at prevailing rates, projected savings are assumed to remain constant, and the payback period is expressed as a single figure. On the surface, this looks reliable, but it does not reflect how conditions change in practice. Energy costs fluctuate, maintenance needs increase over time, and store operations vary day by day. Relying on fixed values masks these variables and can lead to misleading or ill-informed conclusions.

Monte Carlo simulation addresses this challenge. Instead of producing one outcome, it runs thousands of scenarios across defined probability ranges for each input variable. The results are presented as a range of outcomes with their associated probabilities, rather than absolutes. This enables a more nuanced assessment of risk and return, aligning the investment model with the uncertainty that retailers actually face.

This blog looks at why probabilistic modelling provides a stronger basis for investment decisions in refrigeration technology, how Monte Carlo methods work in practice, and the advantages they offer over single-point approaches.

Deterministic vs probabilistic modelling in refrigeration technology investment

The risks of relying on single-point estimates. Most refrigeration technology investment models are deterministic. They take a fixed set of assumptions, such as energy price, cabinet performance, and maintenance costs, and calculate a single outcome. A model might state that the payback period is a fixed number of years or that lifetime savings will reach a particular figure. These results give the appearance of precision, but if energy prices change over time or if maintenance proves more demanding, the outputs quickly lose any credibility. Worse, deterministic models are more liable to input manipulation to deliver a desired single-point outcome.

Probabilistic modelling addresses this weakness. Instead of relying on fixed inputs, it assigns probability distributions to each variable. For example, energy costs might be represented as a range that reflects regional or demand-based variations in pricing. Inflation indices, deployment timing, and forecasts of carbon intensity in supply can be modelled in the same way. Using Monte Carlo methodology, thousands of simulations are run, drawing input values randomly from these probability distributions, thereby generating a spectrum of aggregated results.

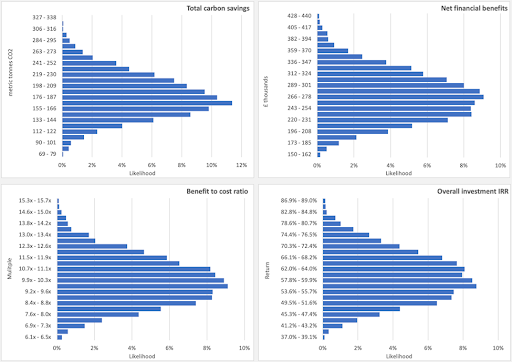

The outcome? It is not a single figure but a histogram showing possible outcomes with their associated probabilities. In the figure below, we show outcome ranges for investment returns, benefit-to-cost ratio and carbon savings for a store-level investment modelled over a 10-year timeframe.

For example, results may show a central tendency towards a saving of 173-183 tonnes of CO₂, but a broad overall high and low outcome range. This approach provides the investment board with the ability to judge the likelihood that an investment meets a specific hurdle rate, or what the range of outcomes would be within, say, the 95% confidence interval.

This change from deterministic to probabilistic methods reflects how advanced modelling is increasingly being applied by Aerofoil Energy and its clients in technology investment programmes.

Monte Carlo simulation: How it works in refrigeration investment

Monte Carlo methods use probabilistic techniques to generate outcomes based on repeated random sampling. In refrigeration technology investment modelling, it is used to paint a picture of the long-term financial and carbon impact of technology deployment across retailer estates.

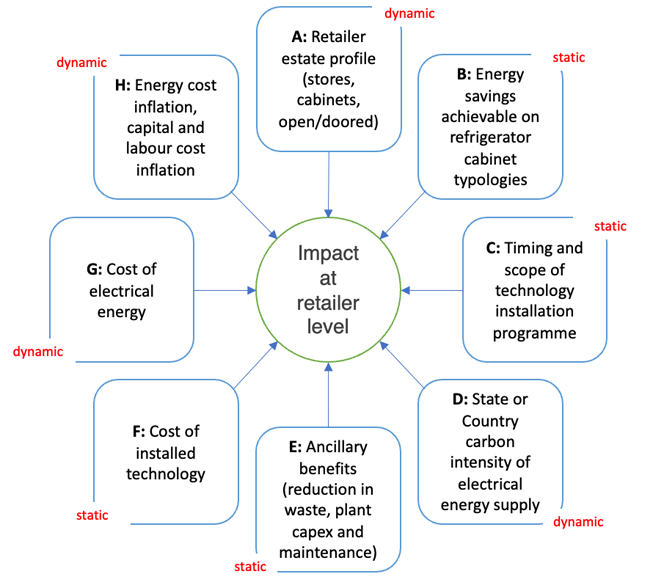

Rather than treating each input as a fixed assumption, the model represents them as probability distributions, in each case capturing the range of values each assumption might exhibit over the life of the investment. The inputs typically include:

Retailer estate size and cabinet mix: number of stores slated for upgrades and the proportion of refrigeration cabinets suitable for deployment.

Deployment timing: phasing of retrofits of existing cabinets and adoption in new or refurbished cabinets over time, modelled over the useful life of equipment.

Baseline cabinet energy consumption: derived from ex-ante energy monitoring data.

Probability distribution of baseline cabinet energy consumption derived from laboratory and in-store monitoring.

Energy savings: derived from independent laboratory and in-store measurements following technology deployment.

Carbon intensity of supply: based on government, NGO and academic data, with changes over time modelled using a constrained random walk.

Electricity prices: prevailing industry tariffs or disclosed retailer contracts, reflecting regional or demand-based variations.

Inflation factors: energy, capital and labour costs modelled to reflect economic cyclicality and interdependencies (for example, capital costs to energy costs).

One possible variation in inflation over time, based on a ‘random walk’ within periodic economic cycles.

Schematic of the probabilistic Monte Carlo model. Inputs included retailer estate size, cabinet typology, energy savings distributions, deployment timing, carbon intensity of supply, adoption rates, technology costs, electricity prices and inflation.

Each Monte Carlo simulation randomly selects values from each of these input distributions. Typically, between 8,000 and 10,000 simulations are run to generate outcomes, which can then be summarised statistically as a histogram or used to report a range of results within a defined confidence interval.

For Aerofoil Energy’s investment models, the aggregated results are expressed as probability distributions for:

Avoided carbon emissions: at retailer, national and regional levels.

Financial viability: the investment case expressed in monetary, rate of return, benefit/cost ratio and payback terms

In the next section, we’ll show a real-life example of Monte Carlo simulation methods being used to evaluate the financial and carbon impact of refrigeration technology across major international retailers.

Case study: Elite project application

Aerofoil Energy applied probabilistic models for its Elite project, a research and development programme designed to establish a new benchmark in refrigeration efficiency. The objective was to estimate the carbon impact of the technology under development.

How it was done

Variables such as with vs without technology cabinet energy consumption, and grid carbon intensity, were modelled to reflect inherent uncertainty and time-based variations.

Technology deployment was modelled to reflect both phased retrofits and factory-fit to new cabinets over time.

Thousands of iterations were run to calculate the likely range of carbon outcomes.

What it showed

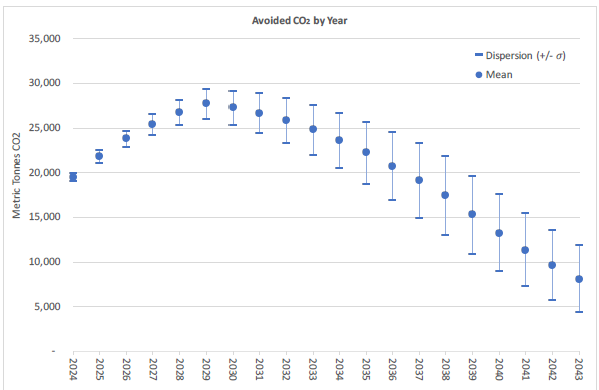

The results were presented to show how avoided carbon emissions would change over time, reflecting the phased adoption of Elite technology set against the gradual removal of carbon from a country’s electrical energy generation mix.

In the UK, adoption of Elite technology across a select group of grocers was estimated to avoid 0.45 million tonnes of CO₂ over a 20-year period.

Time series output showing annual avoided carbon emissions from the adoption of Elite technology in the UK.

In North America, the potential impact was 3.6 million tonnes of avoided CO₂, with Japan/Australia at 1.75 million tonnes and Europe at 1.72 million tonnes.

Time series output showing annual avoided carbon emissions from adoption of Elite technology in the USA and Canada. Note that continuing high levels of fossil-fuel generation in the energy mix in the region results in higher levels of CO2 savings from Elite technology in the long run, compared with the UK and Europe.

Globally, the total impact was between 6.8 and 8.1 million tonnes of CO₂ avoided.

The outcome

Since the Elite project, Aerofoil Energy has embedded probabilistic modelling into its standard business-case assessments for clients, giving retailers a complete view of both financial and carbon impacts. By combining engineering expertise with advanced financial modelling, Aerofoil Energy strengthens the credibility of business cases presented at the board level, supporting more confident and well-informed decision-making.

Building investment cases that reflect reality

Refrigeration technology investments cannot be judged on fixed assumptions. Energy costs fluctuate, operational behaviour is irregular, and maintenance needs increase with cabinet age. Deterministic models compress these variables into a single figure, which creates the illusion of certainty but conceals the risks that affect long-term performance.

Probabilistic modelling provides a more sophisticated view. By applying Monte Carlo methods to simulate thousands of possible outcome scenarios, it ensures that investment strategies are built on evidence that captures both variability and risk. This provides clients with confidence that decisions are grounded in the conditions they face today and into the future.

If you are reviewing your refrigeration strategy, our team can share the probabilistic modelling outputs and case examples that leading retailers are already using to inform their decisions. Get in touch.

Further reading: